Product Description

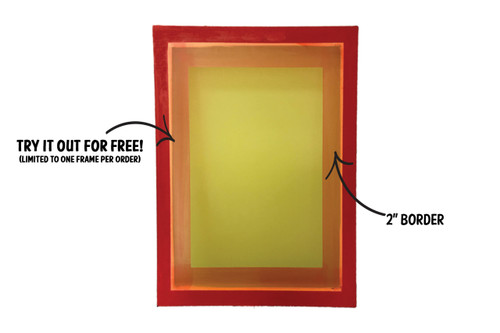

25 X 36 Aluminum Screen Printing Frames Stretched With Saati Hitex Mesh (Standard Thread Mesh).

Why Spot Color Supply Frames??

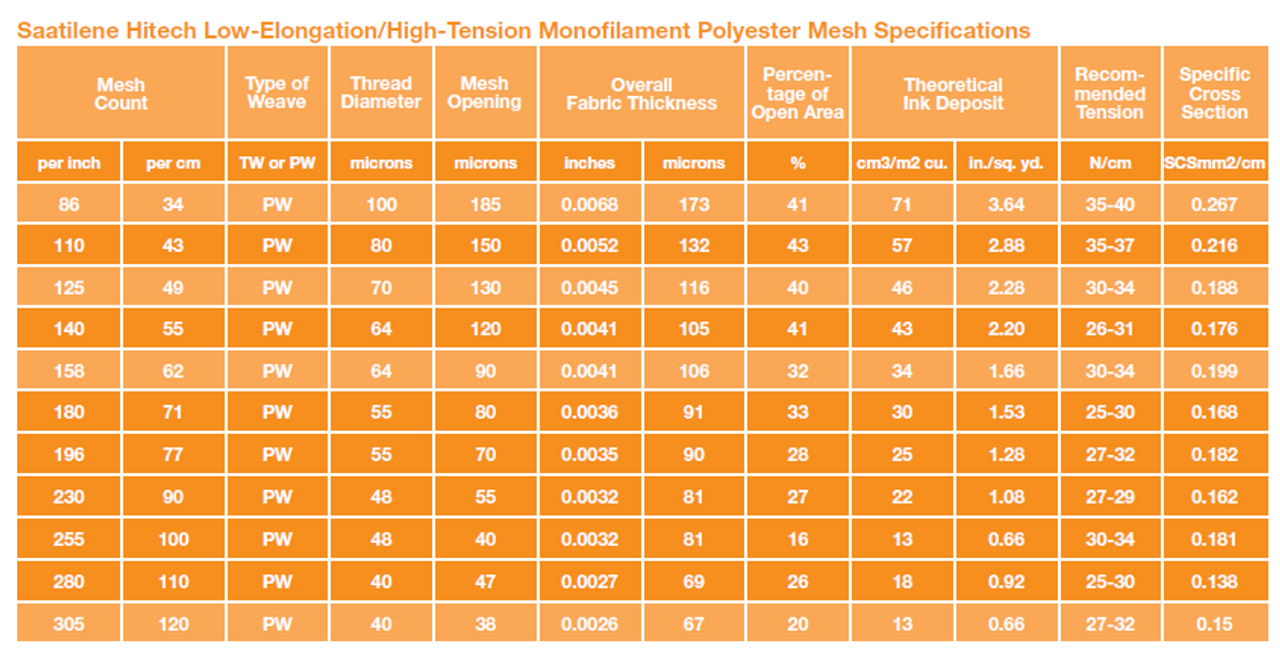

- We ONLY use high quality mesh (No unknown house brands here!!)

The heart of every screen printing frame is the mesh it is stretched with. Just because mesh is labeled as low elongation doesn't mean it is true. Trust the leaders in our industry, Saati and Murakami have been manufacturing high tension, low-elongation mesh for many years.

- All frames are prepped using a Grunig G-Prep 320

In our quest to make the best pre-stretched frames available, we found frame preparation to be difficult to accomplish by hand. The factory bead blast on most frames is a less than perfect glue surface, and belt sanders/grinders gave inconsistent results. The Grunig G-Prep 320 was the answer. The rotating cutter leaves a consistent highly textured surface, perfect for frame glue adhesives.

- Starting tension is 28-32 newtons depending on mesh counts.

High tension screens simply print better... Higher tension equals more open area and lower off contact. No name mesh wont cut it (We tried). This is yet another reason why we only use High Quality Saati and Murakami mesh. Frames are stretched to 28-32 newtons expecting them to settle around 23-25 newtons.

- High Tension is an available option. (32-34 newtons)

Are you a tension snob...? We have the frames for you!! Our equipment has been heavily modified to allow stretching to the manufacturers maximum tension levels. This results in even larger open area, lower off contact, and even faster prints.

- We only use the best adhesives.

2 Part Polyurethane glue is very chemical resistant, After grinding we pre-coat the frame with adhesive to create the best possible bond between the aluminum and mesh. plus once cured it has a rubbery texture that is easier on mesh and your hands.

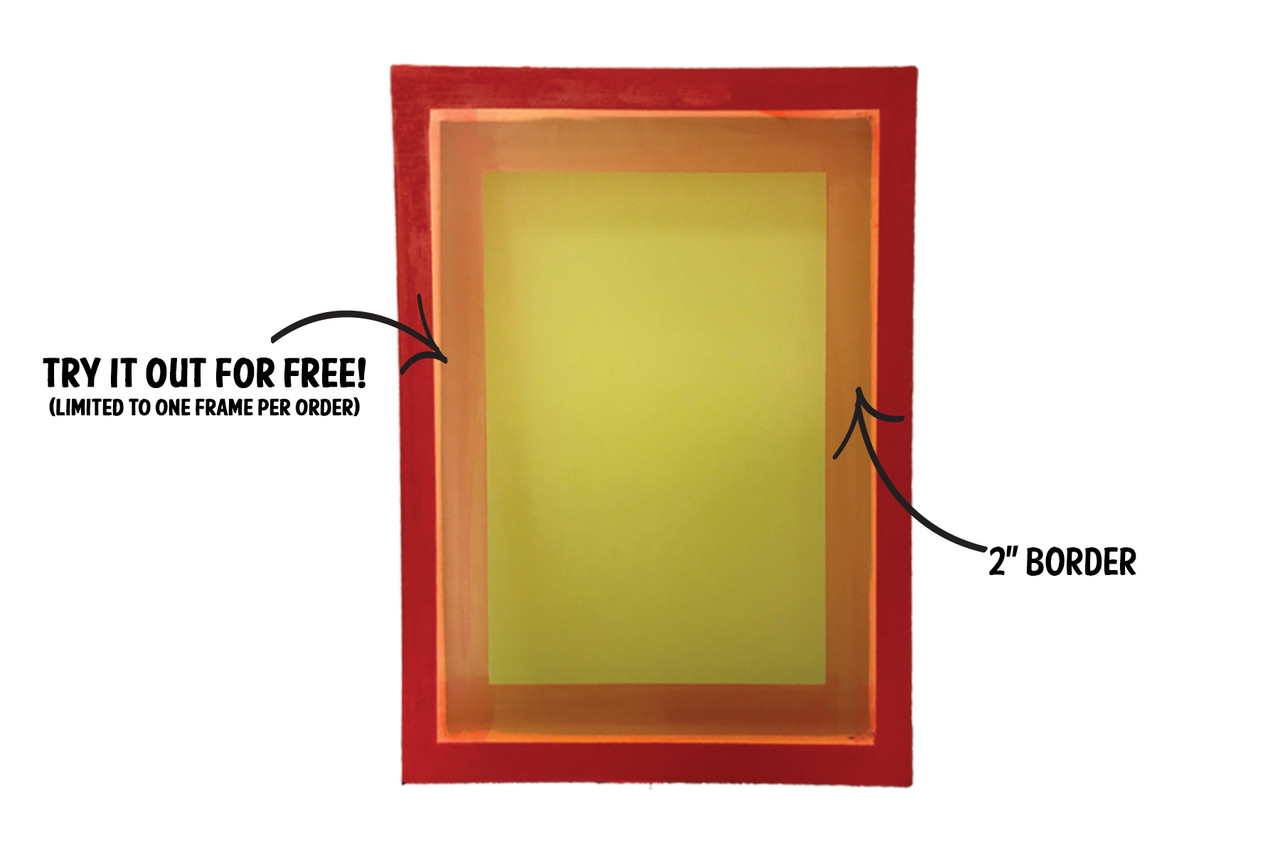

- Permanent blockout is available

Tired of wasting time and money on tape? Try permanent blockout!! Our new and improved blockout is extremely chemical resistant, and adds an additional layer of protection to the frame adhesive. We then finish off with a bead of silicon around the inside edge. Just coat, burn, and its ready for the press.

*may add one day to production time*